Reliable Ball Bearings in Austin, Laredo, Victoria & San Antonio, TX

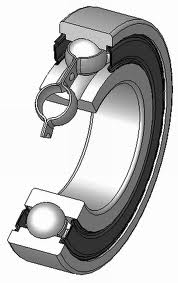

Ball Bearings

Tapered Roller Bearings

Cylindrical Roller Bearing

Spherical Roller Bearing

Needle Roller Bearing

Proudly Serving Southern Texas

If ball bearings are essential to getting your job done, turn to Bohls Equipment to find what you need. We have a massive selection of ball bearings and all the other industrial parts you need to complete the job. Our selection of industrial parts includes electric motors, V-belts, sheaves, roller chains, chain sprockets, oil and grease seals, hydraulic hoses, hydraulic fittings, conveyor belts, and more. Contact us today to place an order for bearings and equipment you need. We have the finest selection of industrial parts in San Antonio, TX; Austin, TX; Laredo, TX; and Victoria, TX.